Applications of Hairpin Stators in Modern Industrial Automation Systems

In modern industrial automation, efficiency, reliability, and precision are crucial for optimal performance. One technology that has gained significant attention in recent years is the use of hairpin stators in electric motors. These innovative components, combined with motor hairpin technology, offer enhanced performance, reduced energy losses, and longer operational lifespans, making them ideal for industrial automation systems where consistent, high-quality operation is essential.

Understanding Hairpin Stators

What Are Hairpin Stators?

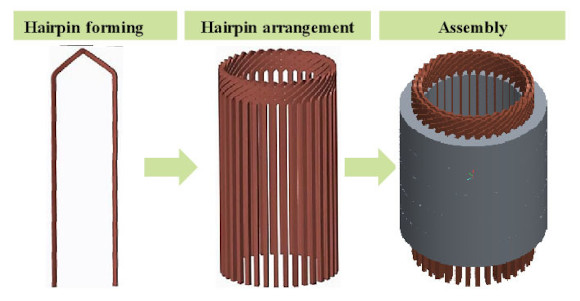

Hairpin stators are a type of motor stator design where the windings are made using flat, rectangular wires bent into a hairpin shape. These hairpins are inserted into the stator slots and welded at their ends to form a complete coil. This method contrasts with traditional round wire windings, offering a denser and more efficient winding structure.

How Hairpin Technology Works

In a motor hairpin, the flat wires allow for tighter packing within the stator slots. This results in reduced electrical resistance and improved thermal management. The design ensures better energy conversion efficiency and helps maintain stable performance under high load and continuous operation—qualities essential for industrial automation environments.

Advantages of Hairpin Stators in Industrial Automation

1. Higher Efficiency

Industrial automation systems often operate continuously for long periods, making energy efficiency a top priority. Hairpin stators provide superior electrical performance by minimizing resistance and reducing energy losses. This increased efficiency translates into lower operational costs and reduced heat generation, improving overall system performance.

2. Enhanced Thermal Management

Heat accumulation can degrade motor performance and shorten its lifespan. The flat design of motor hairpin windings allows for better heat dissipation, which helps maintain optimal operating temperatures. Effective thermal management ensures that motors can run continuously without overheating, even in demanding industrial settings.

3. Greater Power Density

Hairpin stators allow for more copper to be packed into the same stator volume, resulting in higher power density. This means motors can deliver greater torque and power without increasing their size. In industrial automation, where space is often limited, this advantage is particularly valuable for compact machinery and robotic applications.

4. Improved Reliability and Durability

Industrial systems demand motors that can withstand continuous operation and harsh conditions. Hairpin stators offer mechanical robustness due to their rigid winding structure, reducing vibration-related wear and tear. The combination of efficient cooling and durable construction ensures long-term reliability, reducing maintenance needs and downtime.

5. Reduced Electromagnetic Losses

The precise geometry of hairpin stators minimizes electromagnetic losses, improving overall motor efficiency. This feature is especially important in high-speed or high-load automation equipment, where reducing losses directly impacts energy consumption and performance consistency.

Applications in Industrial Automation

Robotics and Automated Machinery

Robotics systems rely heavily on precision, speed, and efficiency. Motor hairpin technology ensures that motors driving robotic arms or automated machinery maintain smooth, accurate movements. The high efficiency and thermal management of hairpin stators help prevent overheating during extended operation, making them ideal for 24/7 automated production lines.

Conveyor Systems

Conveyor systems in manufacturing plants require motors that can handle continuous operation and variable loads. Hairpin stators improve efficiency and reliability, reducing energy costs and maintenance requirements. Enhanced thermal management ensures consistent performance even under heavy-duty workloads.

CNC Machines and Precision Tools

Computer Numerical Control (CNC) machines and precision tools demand motors with high torque and stable performance. The compact, high-power design of hairpin stators allows these motors to deliver precise movements, increasing manufacturing accuracy and product quality.

Packaging and Material Handling Equipment

Packaging lines and material handling systems often operate at high speeds, requiring durable and efficient motors. Hairpin stators provide the necessary power density, thermal management, and reliability to keep these systems running smoothly, reducing downtime and improving overall productivity.

Renewable Energy Integration

Some industrial automation systems integrate renewable energy sources like solar or wind. Motors with hairpin stators can handle fluctuating energy inputs efficiently, maintaining performance while reducing energy losses. This adaptability makes hairpin technology a forward-looking choice for sustainable industrial operations.

Design and Manufacturing Benefits

Simplified Production

Hairpin stators can be manufactured using automated processes that insert and weld hairpin wires with high precision. This reduces manual labor, ensures consistent quality, and allows for scalable production to meet industrial demand.

Flexibility in Motor Design

The use of hairpin stators provides engineers with flexibility to optimize motor design for specific applications. Whether the goal is high torque, compact size, or energy efficiency, hairpin stators can be tailored to meet precise industrial requirements.

Future Trends in Industrial Automation

As automation technology continues to evolve, the demand for more efficient, reliable, and compact motors is increasing. Hairpin stators are poised to play a critical role in this evolution. Advances in materials and manufacturing techniques promise even better performance, making motor hairpin technology central to next-generation industrial automation systems.

Conclusion

The use of hairpin stators in industrial automation represents a significant step forward in motor technology. By combining efficiency, reliability, and durability, motor hairpin technology addresses the demanding requirements of modern industrial systems. From robotics to conveyor systems and CNC machines, hairpin stators enhance performance, reduce energy consumption, and extend motor lifespan. As industries continue to push for smarter, more efficient automation solutions, hairpin stators are set to become a key component in powering the factories and systems of the future.